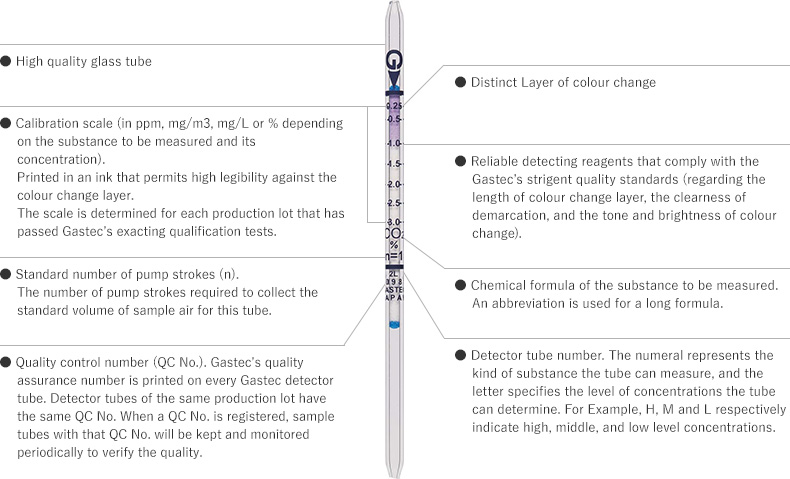

GASTEC Detector Tubes indicate concentrations directly by way of a calibrated scale printed on the tubes. At GASTEC, we endeavour to achieve highest quality detector tubes for analysing airborne gases/vapours, as well as pollutants in soil and water through our advanced state-of-the-art research and development. Through our efforts we have acquired a solid reputation among our customers in virtually all sectors of industry, commerce and society. Tubes are now available for more than 500 different applications.

Features

- On-site measurements can be performed easily by anybody, anytime and anywhere, in a short time

- Easy-to-check direct reading possible due to the calibrated scale directly printed on the tube

- An extensive measuring range can be obtained by adjusting the sampling volume

- In order to assure high precision, each production lot is tested and calibrated independently, Each detector tube has its own quality control number printed on the tube

- Long shelf-life with excellent long-term stability

Gas Sampling Pump Features

The built-in tip breaker incorporates a diamond edge for maximum durability that cuts the surface of the detector tube. This makes the tip breaking much easier, safer and convenient. Discarded tips are deposited in a storage bin for safe and easy disposal.

The pump piston has been designed with a smaller diametre so that the handle can be pulled out with even less effort. This permits anyone to operate the pump easily. Also, GASTEC Pump Model GV-110 and GV-100 meet the leakage test of EN1231, Workplace atmospheres-Short term detector tube measurement systems-Requirements and test methods, 4.2 Detector tube pump, 4.2.2 Leakage "The detector tube pump with the closed detector tube connection shall be tight, so that during the first minute of a pump stroke the leakage rate does not exceed 3mL/min." The GASTEC pump shaft shows you the leakage rates with a red line.

The pump body is covered with a soft elastomer, with the middle portion narrower than the ends to ensure a firm grip on the pump cylinder. The other outer surfaces of the pump are made of non sparking materials of ABS resin except for the opening of the tube tip cutter, which is made of chromed stainless steel.

The full-stroke (100mL) and the half-stroke (50mL) positions are marked exactly by the red line on the pump shaft, and the handle is precisely locked at those positions. The attached flow finish indicator tells you automatically when the stroke is complete. When the white disk pops out,the sample is complete.

The automatic stroke counter built in model GV-110 (in Model GV-110S) gas sampling pump can track up to ten pump strokes automatically so there is no chance of miscounting.

Operating procedures (Simple 3-step measuring)

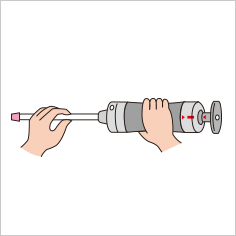

- 1.

- Break off both ends of the detector tube. Insert the tube into the rubber inlet.

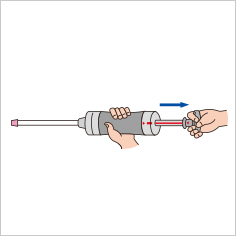

- 2.

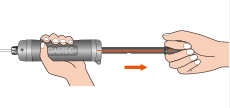

- Pull out the handle until it is locked. Wait until the sampling time has elapsed.

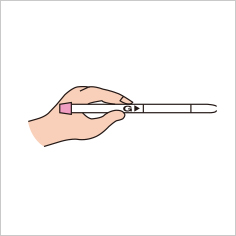

- 3.

- Read the measurement at the end of the coloured layer.

Video instruction

Airtightness test

If the sampling pump is not airtight, measurements will not yield correct results. Before starting to measure, be sure to verify that the sampling pump is really airtight.

- 1.

- First, confirm that the inlet nut is not loose.

- 2.

- Insert a detector tube (with both tips intact) into the rubber tube inlet of the sampling pump.

- 3.

- With the handle fully pushed in, align both of the guide marks (red line + triangle) on the pump (tail-end block) and the handle (▲100).

- 4.

- Pull out the handle in one thrust until it is locked, and then release the handle. Wait until the sampling time (approx. 1 minute) has elapsed.

- 5.

-

Grasp the handle and turn it 90 degrees. If the pump is completely airtight, the handle should readily return to its original position; with the handle's demarcation read line fully concealed.

Note)

When you return the piston, please ease it back gradually (lightly holding on to it so it does not snap back in one thrust. (Since there is a vacuum inside the cylinder, the handle tends to return rapidly). If it snaps back too hard, the impact can damage the pump causing it to malfunction.

Primary causes of leakage in gas sampling pumps are looseness of the inlet nut, porosity of the inlet rubber, impure or insufficient sealing grease, etc. Please perform the necessary maintenance according to the procedures described in the sampling pump instructions manual. If the pump still leaks after performing the maintenance procedures according to the manual, immediately discontinue use, and contact your authorized GASTEC representative.

Video instruction

Product search

Product search

-

Detector tube Search

-

Search other products

-

Product search